Are you tired of manually filling bags for your packaging needs? Say goodbye to the hassle and inefficiency with a bag filling machine! This revolutionary equipment is designed to streamline your packaging process, saving time and increasing productivity. In this blog post, we will guide you through choosing the best bag filling machine for your specific requirements. Get ready to revolutionize your packaging operation with the perfect bag filling solution.

Different Types of Bag Filling Machine

When it comes to bag filling machine, there are various types available to suit different packaging needs.

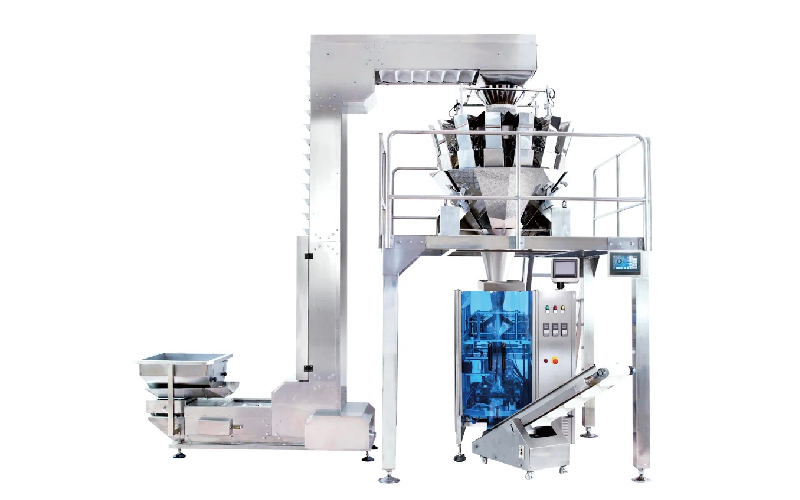

One common type is the vertical form fill seal machine, which can efficiently package products like powders, liquids, and granules into bags.

Another option is the open-mouth bagging machine, ideal for filling larger bags with bulk materials such as grains or pet food.

For more delicate items that require gentle handling during filling, a gravity filler might be the best choice.

If you need to package items in pre-made bags with zippers or spouts, a rotary pouch filling machine could be the perfect solution.

Each type of bag filling machine has its own advantages and capabilities depending on the specific requirements of your packaging process.

Factors to Consider When Choosing a Bag Filling Machine

When it comes to choosing the best bag filling machine for your packaging needs, there are several key factors to consider. You need to evaluate the type and size of bags that will be filled by the machine. Different machines are designed for various bag sizes and materials, so this is a crucial consideration.

Another important factor is the speed at which you need the machine to operate. Some machines can fill bags at a much faster rate than others, so understanding your production requirements is essential in making the right choice.

Additionally, it’s vital to look at the level of automation and customization options offered by different bag filling machines. Depending on your specific packaging process and product characteristics, you may require certain features like weighing systems or sealing mechanisms.

Considering factors such as budget constraints, maintenance requirements, and technical support available from manufacturers will also play a significant role in selecting the most suitable bag filling machine for your business.

The Importance of a Bag Filling Machine in Packaging

When it comes to packaging products efficiently and effectively, having the right bag filling machine is crucial. These machines play a vital role in streamlining the packaging process, saving time and labor costs for businesses.

By automating the filling of bags, these machines ensure consistency in product weight and reduce the risk of human error. This not only improves overall productivity but also enhances product quality and customer satisfaction.

Bag filling machines are versatile tools that can handle a wide range of products, from powders to granules to liquids. They offer flexibility in packaging options, allowing businesses to meet diverse packaging needs with ease.

Investing in a high-quality bag filling machine can significantly impact your bottom line by increasing efficiency, reducing waste, and improving overall operational performance. It’s an essential asset for any business looking to optimize their packaging processes and stay competitive in the market.

Types of Bag Filling Machine

Bag filling machines come in various types to cater to different packaging needs. Gravity-fed bag fillers are suitable for free-flowing bulk materials like grains, seeds, and powders. Auger fillers are ideal for filling dry products consistently into bags with precision. For liquids or viscous products, consider using a piston filler machine that ensures accurate dosing.

Another type is the vibratory feeder system, which is great for fragile or delicate products that need gentle handling during the filling process. If you require high-speed packaging, a rotary valve bag filler may be the best choice as it can fill multiple bags simultaneously. Vacuum bagging machines work well for extending shelf life by removing air from packages before sealing.

Each type of bag filling machine offers unique advantages depending on your specific product and production requirements. It’s essential to select the right one to optimize efficiency and quality in your packaging operations.

Top Features to Look for in a Bag Filling Machine

When it comes to choosing the best bag filling machine for your packaging needs, there are several key features to keep in mind. Consider the speed and efficiency of the machine. A fast filling rate can significantly increase productivity.

Another important feature to look for is versatility. Opt for a machine that can handle various types and sizes of bags without compromising on quality. Additionally, ensure that the machine offers precise weighing accuracy to avoid product wastage.

Durability is also crucial when selecting a bag filling machine. Look for machines made from high-quality materials that can withstand continuous use in a demanding production environment.

Furthermore, consider ease of operation and maintenance. A user-friendly interface and accessible maintenance procedures can save time and reduce downtime.

Check if the bag filling machine offers customization options to tailor it according to your specific packaging requirements.

Maintenance and Cost Considerations

When considering a bag filling machine for your packaging needs, it’s essential to factor in maintenance and cost considerations. Regular maintenance is key to ensuring the machine operates efficiently and minimizes downtime. This includes routine inspections, cleaning, and parts replacement when necessary.

Before investing in a bag filling machine, evaluate the total cost of ownership, including not just the initial purchase price but also ongoing maintenance costs. Consider factors like energy consumption, spare parts availability, and service contracts that may impact long-term expenses.

Choosing a bag filling machine with easy-to-access components can help reduce maintenance time and costs. Look for machines with user-friendly interfaces that allow for quick troubleshooting and repairs when needed. Additionally, consider investing in training for your staff to properly operate and maintain the equipment effectively.

By taking into account both maintenance requirements and overall costs associated with a bag filling machine upfront, you can make an informed decision that aligns with your budget and operational needs.

Conclusion

Choosing the best bag filling machine for your packaging needs is essential to streamline your production process and ensure efficiency. By understanding the different types of bag filling machines available, considering key factors such as speed, accuracy, and versatility, and evaluating maintenance and cost considerations, you can make an informed decision that meets your specific requirements.

Investing in a high-quality bag filling machine can significantly impact your packaging operations by improving productivity, reducing waste, and enhancing overall product quality. With the right features like adjustable fill weights, multiple bag sizes compatibility, user-friendly controls, and easy maintenance capabilities in place, you can optimize your packaging workflow effectively.

Remember to choose a bag filling machine from a reputable manufacturer with a track record of reliability and excellent customer support. Regular maintenance checks and proper training for operators are also crucial for maximizing the lifespan of your equipment and ensuring consistent performance.